Micro-Strip Tool

Micro-Strip® stripping tools from Micro Electronics, Inc. strip buffered fiber up to 2360µm, and jacketed fiber up to 3.5 mm quickly and easily.

Soft-Strip Tool

Thermal stripping tools from Micro Electronics, Inc. utilize the patented non-nicking Soft-Strip® stripping tool system.

Non-Thermal Stripping Procedure

PROPER TOOL SELECTION

Select the proper tool and components for either fiber stripping or jacket stripping by referring to the tables on the back page. If necessary, install proper fiber guide, fiber guide lock and cutter blade set.

STRIPPING PROCEDURE|

(BUFFERED OPTICAL FIBER

USING MS-1-FS TOOL)

1. Hold tool in one hand, fiber in the other. Keep handles in fully expanded position. Insert fiber through fiber guide until end aligns with rule markings to match desired strip length.

2. Squeeze handles closed. Cutter blades are now scoring the buffer or coating.

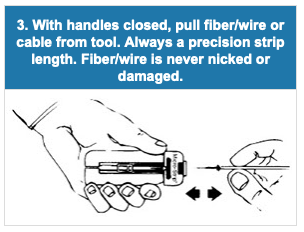

3. While maintaining a slight pressure to keep the cutter closed, withdraw fiber from tool, completing the stripping process.

PROPER TOOL SELECTION

Select the proper tool and components for either fiber stripping or jacket stripping by referring to the tables on the back page. If necessary, install proper fiber guide, fiber guide lock and cutter blade set.

STRIPPING PROCEDURE

(BUFFERED OPTICAL FIBER

USING MS-1-FS TOOL)

1. Hold tool in one hand, fiber in the other. Keep handles in fully expanded position. Insert fiber through fiber guide until end aligns with rule markings to match desired strip length.

2. Squeeze handles closed. Cutter blades are now scoring the buffer or coating.

3. While maintaining a slight pressure to keep the cutter closed, withdraw fiber from tool, completing the stripping process.

Note: Never leave tool with latch in locked position. This can cause Delrin spring to take set, preventing handles from opening fully. When stripping hard, tough or thick jackets, it is necessary to use latch bar. Lock bar out of the way by tightening the screw.

Thermal Stripping Procedure

Strip outer jacket (if any) using the Soft-Strip non-thermal tool. Install and connect battery(s), or install and connect AC adapter. Install proper cutter blade set, fiber guide and fiber guide lock.

HEATER OVEN

Unit is activated when handles are closed. Close handles only when stripping. Check heater operation by closing handles firmly for no longer than ten seconds. Nose end of heater should be warm to the touch.

After stripping operation, remove heater oven from tool and clean with the brush provided (spring assembly in later models include automatic scrap ejector). Reinsert, making sure that heater oven is pushed completely forward toward the blade area and snaps into place. The 2˝ heater oven area should be visible at front of tool so operator can monitor positioning and preheating of coating.

PROCEDURE

1. Insert fiber through fiber guide and into heater oven to desired length. Be sure buffered fiber is flat in the oven channel. Always allow at least 1/8˝ gap from fiber tip to end of oven channel. Otherwise, heater oven movement will cause fiber to buckle up and out of the heating zone.

2. Close handles completely. Blades are precisely aligned for concentric scoring without cladding, core, or conductor damage. Heater oven is automatically activated to start the softening process.

3. Keep handles closed (AA 10-20 seconds, -V or AC adapter 4-8 seconds) for optimum softening. Then, begin to pull the fiber, slowly increasing pull force until coating releases from the fiber. Remove the fiber from the tool with a smooth, even motion.